On this page

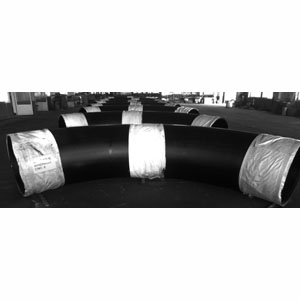

Types of Pipe Bend

Long radius bend: This type of bend has a larger radius compared to other bends, allowing for a smoother flow and reduced pressure drop. It is often used in applications where fluid flow needs to be maintained, such as in water distribution systems.

Short radius bend: As the name suggests, this bend has a smaller radius, making it ideal for applications with space constraints. However, the flow characteristics may be affected due to the sharp turn.

90-degree bend: This is a standard bend that changes the direction of the pipe by 90 degrees. It is commonly used in plumbing, HVAC, and industrial piping systems.

45-degree bend: Similar to the 90-degree bend, this bend changes the direction by 45 degrees. It provides a smoother change in direction compared to a sharp turn, reducing the potential for turbulence in the flow.

U-bend: This bend has a U-shaped configuration, allowing the pipe to reverse its direction. It is often used in applications where a compact layout is required, such as heat exchangers or condensers.

Short radius bend: As the name suggests, this bend has a smaller radius, making it ideal for applications with space constraints. However, the flow characteristics may be affected due to the sharp turn.

90-degree bend: This is a standard bend that changes the direction of the pipe by 90 degrees. It is commonly used in plumbing, HVAC, and industrial piping systems.

45-degree bend: Similar to the 90-degree bend, this bend changes the direction by 45 degrees. It provides a smoother change in direction compared to a sharp turn, reducing the potential for turbulence in the flow.

U-bend: This bend has a U-shaped configuration, allowing the pipe to reverse its direction. It is often used in applications where a compact layout is required, such as heat exchangers or condensers.

More about Pipe Bend

Material Composition: Materials commonly used for pipe bends include Carbon Steel, Stainless Steel, Alloy Steel, Copper, PVC (Polyvinyl Chloride), HDPE (High-Density Polyethylene), Brass, and Cast Iron.Application: Pipe bends are essential components in many industries, including oil and gas, chemical, water treatment, and power generation.

Standards: Pipe bends are manufactured by conforming to such standards as ANSI/ASME B16.49, ASTM A234/A234M, ASTM A403/A403M, ASTM A815/A815M, MSS SP-75, EN 10253-2, ISO 15590-1 and DIN 2605-1