-

The Failure Analysis of the Stainless Steel TP304 Tee (Part One)

Posted: 03/08/2022 09:58:56 Hits: 4Abstract: The stainless steel TP304 tee used in the denitration facility of the power plant cracks. Through the composition analysis, the macroscopic and microscopic analysis of the fracture, the microstructure observation and the hardness test, combined with the production... -

Research on Cold & Hot Forming of S31254 180° Elbows

Posted: 02/23/2022 08:14:42 Hits: 6Abstract: The S31254 180° R=1D sharp turning elbow used in the high-temperature pyrolysis furnace of a company in the United States is currently manufactured by the casting process, and the steel pipe's manufacturing process is now used as the research object. The research... -

Leakages at the Connecting Part Between Flanges & Reducers in Quench Boilers

Posted: 01/25/2022 07:25:15 Hits: 6Abstract: Since April 2016, there have been frequent leaks and fires at the connecting part between the flange and reducer of the cracking furnace quench boiler in 220 kt/a ethylene unit of China National Petroleum Dushanzi Petrochemical. Through various inspections and analyses, it is... -

The Cause Analysis of Perforated Elbows for Cracking Furnaces

Posted: 12/09/2021 10:20:13 Hits: 4Introduction There are 8 cracking furnaces in a workshop, from NO.1 to NO.8. Furnaces from NO.1 to NO.7 are a USC-176C tube cracking furnace, and NO.8 furnace is a USC-12M circulating gas cracking furnace, of which the USC-12M circulating gas cracking furnace has the structure of a... -

Analysis of Failure Causes of Tees in Inlet Pipelines of Hydrocracking Pumps (Part Two)

Posted: 11/27/2021 04:11:00 Hits: 24. Scanning electron microscopy analysis Cut the tee along the crack's propagation direction and performed scanning electron microscopy analysis. The microscopic morphology of the fracture is shown in Figure 6, and the propagation direction of the crack was from the inner wall... -

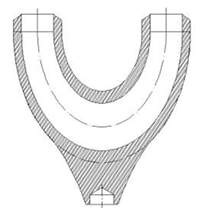

Failure Causes of Tees in Inlet Pipelines of Hydrocracking Pumps(Part One)

Posted: 11/13/2021 08:38:29 Hits: 5Abstract: Through the macro inspection, chemical analysis, metallographic analysis and scanning electron microscopy analysis of the tee of the stainless steel pipeline at the inlet of the liquefied gas pump of a hydrocracking unit of a certain company. It is believed that the cause of the... -

Leakages of Pipe Caps of Hot-wall Tubes of Hydrogen Conversion Furnaces (Part Two)

Posted: 08/09/2021 10:31:31 Hits: 82.7 The analysis of the end of the crack (1) The analysis of the macroscopic fracture: it could be seen that the surface of the fracture was uneven by intercepting the sample; dendritic crystal texture was visible, and the surface was oxidized and black.... -

Leakages of Pipe Caps of Hot-wall Tubes of Hydrogen Conversion Furnaces (Part One)

Posted: 07/29/2021 10:03:43 Hits: 15Abstract: During the operation of the hydrogen manufacturing conversion furnace, the furnace tube and hot-wall tube of the hydrogen manufacturing furnace work at high temperatures, and the medium in the tube is complicated. Cracks are found in the cap of the hot-wall tube... -

Failure Analysis of the Cracking of Stainless Steel Tees in Industrial Pipelines (Part Two)

Posted: 05/10/2021 10:57:21 Hits: 312.6 The scanning electron microscope observation and energy spectrum analysis Sample at A according to the position shown in Figure 3 for the scanning electron microscope and energy spectrum analysis. Scanning electron microscopy results are shown in Figures 4 and 5. The crack fractures mostly... -

Failure Analysis of the Cracking of Stainless Steel Tees in Industrial Pipelines (Part One)

Posted: 04/27/2021 09:22:08 Hits: 18Abstract: An austenitic stainless steel tee in an industrial pipeline of a coal chemical plant cracked and failed in the use process. Inspection and sampling tests are performed for the tee in this article, including macroscopic inspection, hardness measurement, metallographic analysis...