-

Analysis & Preventive Measures for Cracks in Ultra-high Pressure Steam Pipelines

Posted: 06/25/2023 09:55:46 Hits: 484.1 The Analysis of test results Through visual inspection, hardness inspection, composition and metallographic inspection, it is shown that the current performance of the material is consistent with its service time. Compared with the test results in 2006, the overall hardness value dropped significantly,... -

Cracking of Welding Seams of Eccentric Reducers in Ultra-high Pressure Steam Pipelines

Posted: 06/16/2023 11:53:41 Hits: 45Abstract: The cracking process of the welding seam of the reducer on the ultra-high pressure steam pipeline of the 220 kt/a ethylene plant of PetroChina Dushanzi Petrochemical Company was explained. Tests and other methods are used to find the cause of the cracking at the welding seam of the reducer... -

Discussion of Cracks of Reducers

Posted: 05/29/2023 11:44:12 Hits: 17From cracks of the reducer of the cold high-resolution bottom sewage pipeline of the cracked hydrogenation unit, it can be judged that the cracks belong to stress corrosion cracking caused by H2S. The conditions for cracking are as follows: Hydrogen environment There is a critical hydrogen... -

Cracks of Reducers

Posted: 05/10/2023 11:34:46 Hits: 29Abstract: Through the comprehensive analysis of reducers of the cracked residual oil hydrogenation cold high-pressure bottom sewage pipeline, the results show that under high hydrogen sulfide content and high pressure, even if the sulfur content of carbon steel reaches 0.003% (mass fraction), hydrogen-induced... -

Classifications of Stainless Steel Pipe Fittings

Posted: 04/26/2023 06:44:34 Hits: 21A stainless steel pipe fitting is a kind of pipe fittings, including stainless steel elbows, stainless steel tees, stainless steel crosses, stainless steel reducers and stainless steel plugs. The main stainless steel materials are 304, 304L, 316L and 316L. According to the connection method, it can... -

Definition and Chemical Composition of Stainless Steel Pipe Fittings

Posted: 04/07/2023 07:17:47 Hits: 27Definition of stainless steel pipe fittings Stainless steel pipe fittings are commonly used to connect pipelines. They are used to connect pipes, change direction, and regulate the flow of fluids. Stainless steel is a popular material for pipe fittings due to its excellent corrosion resistance, high... -

Alloy Steel Pipe Fittings

Posted: 03/29/2023 03:40:50 Hits: 21.1 Alloy steel elbows Nominal diameters: DN15 to DN1200 Thickness: SCH 5S to XXS. Executive standards: ANIS, JIS, British Standards (BS), German Standards (DIN), Italian Standards (UNI), etc. Materials: ASTM A335 P91, A335 P22, WB36, A335 P11, etc. Uses: Used in natural gas, petroleum, chemical industry,... -

A Carbon Steel Pipe Fitting

Posted: 03/15/2023 09:32:53 Hits: 101. Overview A carbon steel pipe fitting is currently one of the most widely used pipe fittings. Ferroalloys with a carbon content between 0.02% and 2.04% are collectively referred to as steel. The commonly used steel is carbon steel, and its main materials are ASTM A234, ASTM A105 and ASTM A403. The... -

Materials and Classifications of Metal Pipe Fittings

Posted: 02/22/2023 07:40:28 Hits: 11Materials and classifications of metal pipe fittings Pipe fittings play the role of changing the direction, changing the elevation or changing the diameter, closing the pipe end and leading the branch pipe from the main pipe in the pipe system. In petrochemical plants, there are many types of pipelines.... -

Mechanical Properties of the China-russian Pipeline

Posted: 02/10/2023 07:41:13 Hits: 16After the tee is welded, multiple drawings and heat treatments are required. Heat treatment will deteriorate the low-temperature performance of the tee’s welding seam, and the low-temperature toughness of the pipe fittings is the key to restricting the tee’s manufacturing capacity. The toughness... -

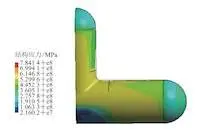

Designing Tees on the China-Russian Eastern Pipeline

Posted: 01/28/2023 11:10:10 Hits: 16Designing structural dimensions 1.1 Design method Among the standard pipe fittings, the tee is the most difficult to process. The structure of the tee destroys the continuity and integrity of the shell due to the opening of the hole. Under the action of external loads (mainly internal pressure), partial... -

Magnetic Particle Inspection of Pipe Fittings with Anti-corrosion Coatings

Posted: 01/16/2023 09:09:57 Hits: 15Abstract: The magnetic particle inspection for pipes and pipe fittings with various specifications and anti-corrosion coatings with different thicknesses is introduced in the construction of coal chemical engineering projects. In a methanol-to-olefins project, there are magnetic pipes and pipe fittings...