-

Metallic Spiral Wound Gaskets: A Versatile Sealing Solution

Posted: 02/29/2024 03:16:50 Hits: 19Metallic spiral wound gaskets stand out as one of the most extensively utilized sealing materials, offering a reliable and cost-effective sealing solution capable of withstanding fluctuations in operating temperature and pressure, thanks to their clever combination of multiple layers of metal... -

Gasket Sealing: Mechanisms and Leak Prevention in Industry

Posted: 02/28/2024 03:23:49 Hits: 163Sealing technology is crucial in industrial applications, especially for pressure vessels, process equipment, power machinery, and connecting pipelines. Gasket sealing is widely used in various industries. This article explores gasket sealing, its mechanism, leakage patterns, and leak mitigation strategies,... -

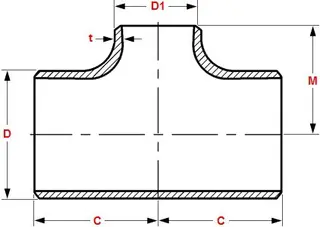

The Role and Advantages of Reducing Tees in Piping Systems

Posted: 02/24/2024 03:05:38 Hits: 163A reducing tee, a crucial component in piping systems, is ingeniously designed to connect pipes of varying diameters, exhibiting outstanding performance when linking dissimilar pipe sizes. Apart from facilitating smooth fluid redirection, it serves multiple functions within a piping network. Let's... -

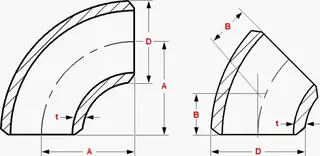

Tips for Enhancing Stability of Welded Pipe Elbows

Posted: 02/21/2024 04:29:06 Hits: 13Welded pipe elbows are integral components in diverse piping systems, where stability is paramount for safety and efficiency. Achieving and maintaining this stability requires a meticulous approach including various aspects of production, handling, installation and maintenance. In this article,... -

Pressure Monitoring Instruments for High-pressure Pipe Fittings

Posted: 02/07/2024 06:37:56 Hits: 16What are high-pressure pipe fittings? High-pressure pipe fittings play a crucial role in various industries, ensuring the safe and efficient transport of fluids under extreme pressures. These pipe fittings are designed to withstand high levels of pressure and prevent leaks or failures that could lead... -

Measures for Leakages of Hydrogen Pipelines in Refining & Chemical Hydrogen Production Units

Posted: 12/19/2023 09:05:11 Hits: 313. The research on the failure 3.1 Design All stainless steel pipes and pipe fittings of this device are ordered according to the "Comprehensive Material Lists" of the detailed engineering design of the design institute, and the material is 0Cr18Ni10Ti. Comply with design specifications "General... -

Leakages of Hydrogen Pipelines in Refining and Chemical Hydrogen Production Units

Posted: 12/11/2023 07:00:21 Hits: 24Leakages of Hydrogen Pipelines Hydrogen, being the most abundant element in the universe, has gained significant attention as a potential alternative energy source. Its use as a clean and efficient fuel has led to the development of hydrogen pipelines for its transportation. However, these pipelines... -

High-pressure Large-diameter Pipe Fittings

Posted: 11/22/2023 10:57:41 Hits: 20High-pressure large-diameter pipe fittings play a crucial role in various industries, ensuring the safe and efficient transport of fluids and gases. These pipe fittings are designed to withstand high pressures, making them essential for applications such as oil and gas pipelines, chemical processing... -

Measures for Temperature Rise of the Fire Pipe Unions (Part Two)

Posted: 10/19/2023 03:19:56 Hits: 183. Cause analysis (1) According to the design and drawing requirements, the generator fire ring pipe and joints are made from stainless steel. However, the internal structure and composition of the ring pipe joints have changed in the manufacturing process, making them magnetic. When the unit is running,... -

Measures for Temperature Rise of the Fire Pipe Unions (Part One)

Posted: 09/12/2023 03:32:41 Hits: 20Abstract: The fire protection system of a hydropower station mainly consists of a gas fire extinguishing system, a water spray fire extinguishing system, and a fire monitoring and alarm system. The fire protection system of a hydropower station plays a very important role in ensuring the safe and stable... -

Inspection of Hydrogen Pipelines in Refining and Chemical Hydrogen Production Units

Posted: 08/23/2023 07:50:47 Hits: 403. Research on the failure 3.1 Design aspects All stainless steel pipes and pipe fittings of this device are ordered according to the detailed engineering design "Comprehensive Material Lists" of the design institute, and the material is 0Cr18Ni10Ti. Conform to design specifications "Design... -

Leakages of Hydrogen Pipeline in Refining and Chemical Hydrogen Production Units

Posted: 08/10/2023 07:20:01 Hits: 26Summary In refining and chemical enterprises, with the development of enterprises and market demand, the national and international requirements for gasoline and other product standards continue to increase, and the number of hydrogenation units continues to increase; the demand for hydrogen continues...