Leakages of Hydrogen Pipelines in Refining and Chemical Hydrogen Production Units

Posted: 12/11/2023 07:00:21 Hits: 24

Leakages of Hydrogen Pipelines

Hydrogen, being the most abundant element in the universe, has gained significant attention as a potential alternative energy source. Its use as a clean and efficient fuel has led to the development of hydrogen pipelines for its transportation. However, these pipelines are not without their challenges, one of which is leakages. Leakages in hydrogen pipelines can occur due to various reasons such as corrosion, mechanical damage, or manufacturing defects. The consequences of such leakages can be severe and pose risks to both human safety and the environment. Hydrogen is highly flammable and can ignite even at low concentrations in the air. Therefore, any leakage can result in explosions or fires that may cause significant damage. In refining and chemical enterprises, with the development of enterprises and market demand, national and international requirements for product standards such as gasoline continue to increase, and hydrogenation units continue to increase. As a result, the demand for hydrogen continues to increase, and the probability of failure increases significantly in the production and operation of hydrogen production units.

1. Failures

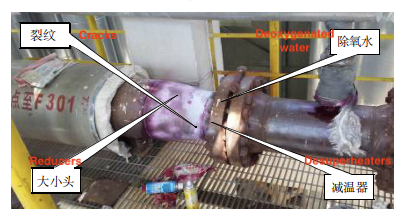

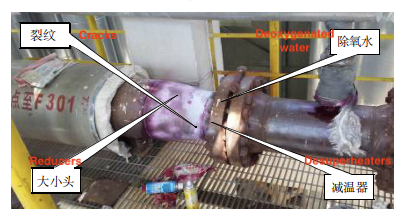

During the inspection of the hydrogen production unit of a refining and chemical company, the personnel found abnormal sounds in the pipeline area from desuperheater II to F-301-1. During the inspection, they found water dripping and intermittent water vapor at the outlet of desuperheater II. After identifying risks, taking precautions and initiating relevant emergency plans, the relevant personnel removed and inspected the insulation of the pipe fittings and found that a circumferential crack with a length of 150mm happens at the small end of the reducer of DN400×DN300 in the pipeline 400-P-22133005 (Figure 1) and leakage occur. According to the situation of the leakage, relevant management personnel on site decided to immediately shut down and organize emergency repairs and other related operations.

Figure 1 The cracked reducer

2. Installation background

The hydrogen production unit is a supporting project for the centralized crude oil processing and refining structure adjustment technology transformation project of a refining and chemical company. It belongs to the E+PC construction model. It is designed by a design institute and is PC general contracted by a construction company. Coking dry gas, Hydrogen dry gas, low fraction gas, and styrene tail gas are used as raw materials for the hydrogen production unit, and the final product is hydrogen. The product hydrogen is used as the hydrogen source for 180×104t/a diesel hydro refining and 200×104t/a hydrocracking unit. The nominal scale of the hydrogen production unit is 60,000 Nm3/h (6x104Nm3/h).

The reducers of the pipeline 400-P-22133005-5K1 of the conversion unit of this device cracked and failed after about one and a half years of operation. The design file shows that the reducer is made from 0Cr18Ni10Ti with BW ends and belongs to seamless concentric reducers. Its size is DN400 × DN300. The design operating temperature is 420°C and the operating pressure is 3.5MPa. The actual operating temperature is 360°C and the operating pressure is 2.6MPa. The medium inside the reducer is a raw gas mixture, in which the steam content is about 81% and the hydrocarbon content is about 16%, and contains small amounts of CO, CO2 and H2. The failed pipe is 400-P-22133005 made from 0Cr18Ni10Ti, with a total length of 10.6 meters, and a wall thickness of 13mm. The transport medium is a raw gas mixture such as hydrogen, methane, carbon monoxide, carbon dioxide and water vapor.

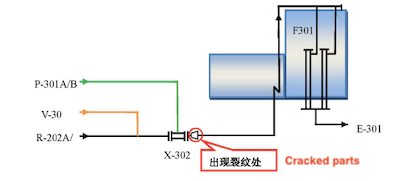

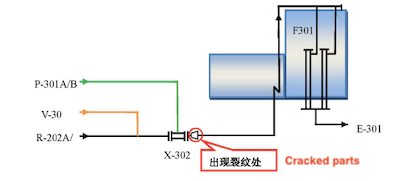

The main process flow of this part(Figure 2): the raw gas is first pressurized by the raw gas compressor; then enters the E302 shell layer and exchanges heat with the shift gas in the tube layer. After the temperature rises, it enters the hydrogenation reactor R201 through the 200-G-22132001-5F1 pipeline. After the hydrogenation reaction, it enters the desulfurization tank R202A/B through the 200-G-22132003-5F1 pipeline, where the raw gas is desulfurized.

Out of the desulfurization tank R202A/B, it passes through the 200-G-22132009-5F1 pipeline 250-MS-22133023-5F1. The superheated steam in the pipeline merges into 300-P-22132004-5K1, enters the 2213-X-302 desuperheater II, and exits from the desuperheater II, which is the pipeline 400-P-22132005-5K1 where the failed reducer of DN400×DN300 is located. The raw gas mixture enters the mixed gas preheater of the convection section of the F-301-1 reformer through the 400-P-22133005-5K1 pipeline. After heat exchange, it enters the reformer F-301 for reaction.

Figure 2 The process flow chart

Hydrogen, being the most abundant element in the universe, has gained significant attention as a potential alternative energy source. Its use as a clean and efficient fuel has led to the development of hydrogen pipelines for its transportation. However, these pipelines are not without their challenges, one of which is leakages. Leakages in hydrogen pipelines can occur due to various reasons such as corrosion, mechanical damage, or manufacturing defects. The consequences of such leakages can be severe and pose risks to both human safety and the environment. Hydrogen is highly flammable and can ignite even at low concentrations in the air. Therefore, any leakage can result in explosions or fires that may cause significant damage. In refining and chemical enterprises, with the development of enterprises and market demand, national and international requirements for product standards such as gasoline continue to increase, and hydrogenation units continue to increase. As a result, the demand for hydrogen continues to increase, and the probability of failure increases significantly in the production and operation of hydrogen production units.

1. Failures

During the inspection of the hydrogen production unit of a refining and chemical company, the personnel found abnormal sounds in the pipeline area from desuperheater II to F-301-1. During the inspection, they found water dripping and intermittent water vapor at the outlet of desuperheater II. After identifying risks, taking precautions and initiating relevant emergency plans, the relevant personnel removed and inspected the insulation of the pipe fittings and found that a circumferential crack with a length of 150mm happens at the small end of the reducer of DN400×DN300 in the pipeline 400-P-22133005 (Figure 1) and leakage occur. According to the situation of the leakage, relevant management personnel on site decided to immediately shut down and organize emergency repairs and other related operations.

Figure 1 The cracked reducer

2. Installation background

The hydrogen production unit is a supporting project for the centralized crude oil processing and refining structure adjustment technology transformation project of a refining and chemical company. It belongs to the E+PC construction model. It is designed by a design institute and is PC general contracted by a construction company. Coking dry gas, Hydrogen dry gas, low fraction gas, and styrene tail gas are used as raw materials for the hydrogen production unit, and the final product is hydrogen. The product hydrogen is used as the hydrogen source for 180×104t/a diesel hydro refining and 200×104t/a hydrocracking unit. The nominal scale of the hydrogen production unit is 60,000 Nm3/h (6x104Nm3/h).

The reducers of the pipeline 400-P-22133005-5K1 of the conversion unit of this device cracked and failed after about one and a half years of operation. The design file shows that the reducer is made from 0Cr18Ni10Ti with BW ends and belongs to seamless concentric reducers. Its size is DN400 × DN300. The design operating temperature is 420°C and the operating pressure is 3.5MPa. The actual operating temperature is 360°C and the operating pressure is 2.6MPa. The medium inside the reducer is a raw gas mixture, in which the steam content is about 81% and the hydrocarbon content is about 16%, and contains small amounts of CO, CO2 and H2. The failed pipe is 400-P-22133005 made from 0Cr18Ni10Ti, with a total length of 10.6 meters, and a wall thickness of 13mm. The transport medium is a raw gas mixture such as hydrogen, methane, carbon monoxide, carbon dioxide and water vapor.

The main process flow of this part(Figure 2): the raw gas is first pressurized by the raw gas compressor; then enters the E302 shell layer and exchanges heat with the shift gas in the tube layer. After the temperature rises, it enters the hydrogenation reactor R201 through the 200-G-22132001-5F1 pipeline. After the hydrogenation reaction, it enters the desulfurization tank R202A/B through the 200-G-22132003-5F1 pipeline, where the raw gas is desulfurized.

Out of the desulfurization tank R202A/B, it passes through the 200-G-22132009-5F1 pipeline 250-MS-22133023-5F1. The superheated steam in the pipeline merges into 300-P-22132004-5K1, enters the 2213-X-302 desuperheater II, and exits from the desuperheater II, which is the pipeline 400-P-22132005-5K1 where the failed reducer of DN400×DN300 is located. The raw gas mixture enters the mixed gas preheater of the convection section of the F-301-1 reformer through the 400-P-22133005-5K1 pipeline. After heat exchange, it enters the reformer F-301 for reaction.

Figure 2 The process flow chart

Post URL: https://www.landeepipefitting.com/leakages-of-hydrogen-pipelines-in-refining-and-chemical-hydrogen-production-units.html

Landee is a professional industrial pipe fitting manufacturer and be well accepted by customers all over the world, we has been producing Pipe Fitting for a variety of applications since 1985. welcome to access our website: https://www.landeepipefitting.com.

Previous: High-pressure Large-diameter Pipe Fittings

Next: Measures for Leakages of Hydrogen Pipelines in Refining & Chemical Hydrogen Production Units

Next: Measures for Leakages of Hydrogen Pipelines in Refining & Chemical Hydrogen Production Units