Metallic Spiral Wound Gaskets: A Versatile Sealing Solution

Posted: 02/29/2024 03:16:50 Hits: 19

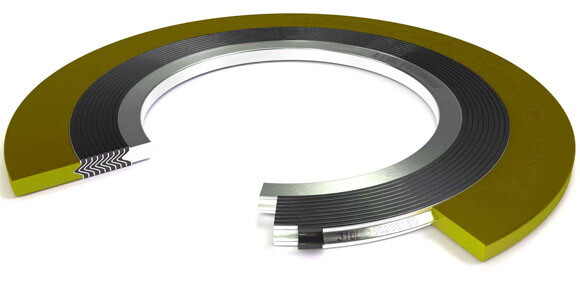

Metallic spiral wound gaskets stand out as one of the most extensively utilized sealing materials, offering a reliable and cost-effective sealing solution capable of withstanding fluctuations in operating temperature and pressure, thanks to their clever combination of multiple layers of metal and filler material. This gasket demonstrates exceptional performance across various conditions, finding widespread applications particularly in industries such as refineries and chemical plants.

1. Manufacturing Process and Structural Design

The manufacturing process of metallic spiral wound gaskets involves the interweaving of formed metal strips and pliable filler materials. This distinctive structure, when compressed between two flanges, forms an extremely effective seal. The key lies in the V-shaped protrusions in the middle of the metal strip, which act like springs, providing outstanding resilience to the gasket when conditions change. The selection of filler material and metal strip can be adjusted to meet the requirements of different chemical mediums, with flexible graphite serving as an ideal choice for applications requiring fire safety.

2. Innovative Design of Inner and Outer Rings

A metallic spiral wound gasket typically includes an outer ring, an inner ring, or both. The outer ring not only ensures alignment with the flanges and limits the compression range of the gasket but also acts as a stop for gasket compression. Meanwhile, the inner ring not only provides additional radial strength but also reduces flange erosion, effectively protecting sealing components and extending their lifespan.

3. Widespread Applications

Metallic spiral wound gaskets, with their exceptional resilience and high strength, have become the ideal choice for various operating conditions and environments. Whether facing high temperatures, high pressures, corrosive media, or requiring fire safety, metallic spiral wound gaskets excel in all scenarios.

4. Key Factors Affecting Gasket Sealing Performance

Achieving effective sealing relies not only on the manufacturing process and structural design of the gasket but also on several other factors:

Material Selection and Adaptability: Metals and filler materials must adapt to various factors such as temperature, pressure, and the medium. Choosing materials like flexible graphite, which are resistant to high temperatures and corrosion, can enhance the adaptability of the gasket.

Scientific Connection Design: Sufficient load must be applied to the connecting parts to counteract the fluid hydrostatic pressure generated by the system's internal pressure, preventing flange separation.

Proper Control of Bolt Load: Proper bolt load is crucial to ensuring that the gasket deforms as required; excessive or insufficient load may lead to leakage.

Refined Surface Finishing: Surface finishing must meet the requirements of the gasket to ensure sealing effectiveness. Non-standard surface finishing may result in poor sealing and increase the risk of leakage.

Scientific Connection Design: Sufficient load must be applied to the connecting parts to counteract the fluid hydrostatic pressure generated by the system's internal pressure, preventing flange separation.

Proper Control of Bolt Load: Proper bolt load is crucial to ensuring that the gasket deforms as required; excessive or insufficient load may lead to leakage.

Refined Surface Finishing: Surface finishing must meet the requirements of the gasket to ensure sealing effectiveness. Non-standard surface finishing may result in poor sealing and increase the risk of leakage.

Metallic spiral wound gaskets, with their outstanding engineering design and wide applicability, provide a reliable sealing solution for the industrial sector. In ever-changing conditions, their innovative design and exceptional performance make them a key technology in the field of sealing.

Post URL: https://www.landeepipefitting.com/metallic-spiral-wound-gaskets-a-versatile-sealing-solution.html

Landee is a professional industrial pipe fitting manufacturer and be well accepted by customers all over the world, we has been producing Pipe Fitting for a variety of applications since 1985. welcome to access our website: https://www.landeepipefitting.com.

Previous: Gasket Sealing: Mechanisms and Leak Prevention in Industry

Next: Understanding Equal and Reducing Tees in Pipeline Engineering

Next: Understanding Equal and Reducing Tees in Pipeline Engineering